Coriolis Flow Meter Pressure Drop

Can be used to measure the flow of corrosive fluids and slurries. Since flow control is often essential measuring the flow of liquids and gasses is a critical need for many industrial applications and there are many different types of flow.

Coriolis Flowmeters Part 3 Flowmeter Design

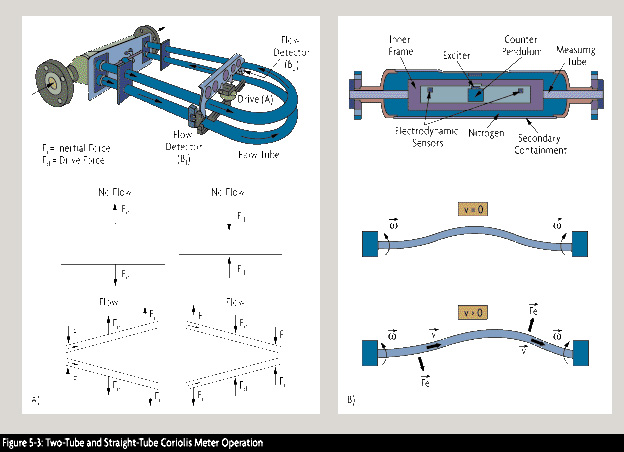

More sophisticated Coriolis meters employ dual-curved tubes for higher sensitivity and lower pressure drop.

. A gas meter is a specialized flow meter used to measure the volume of fuel gases such as natural gas and liquefied petroleum gasGas meters are used at residential commercial and industrial buildings that consume fuel gas supplied by a gas utilityGases are more difficult to measure than liquids because measured volumes are highly affected by temperature and. A Coriolis mass flowmeter measures mass through inertia. The Dall tube is a shortened version of a Venturi meter with a lower pressure drop than an orifice plate.

Advantages of Using Flow Meter Clamp on Ultrasonic. Magnetic flow meter accuracy Magnetic flow meters have a fairly good accuracy of 05 or better for the inline type and 1 2 for the insertion type. The tubes deform and an additional vibration component is added to the oscillation which causes a measurable phase shift in the tubes.

Usually accuracy of a venturi tube is 1 of its full range. In addition in 1835 Gustave Coriolis developed his now well-known formula for inertial force but the Coriolis flow meter didnt begin selling until 122 years later in 1977. Small tubes called.

A flow meter or a flow sensor is an instrument that is used to indicate the amount of liquid gas or vapor moving through a pipe or conduit by measuring linear non-linear mass or volumetric flow rates. Meanwhile from the measurement function because there is no rotating sensor part it is very suitable for those who do not want excessive pressure drop due to the installation of a flow meter. Nominal flow rate is the flow rate at which water at reference conditions causes approximately 145 psig 1 barg of pressure drop across the meter.

Multi-sensor models have higher accuracy. Some industrial control pressure devices include Coriolis flow meters Orifice flow meters and Turbine flow meters. A venturi tube can pass 25 to 50 extra flow than that of an orifice plate keeping the same drop in.

304L L 316L MA and super duplex Y Style Model Nominal line size Nominal flow rate Maximum flow rate. Since the introduction of flow meters into the mass market they have become essential tools in our world. Enter the email address you signed up with and well email you a reset link.

It can be used as liquid gas or air flow meter and the results can be checked against the textbook formula to gain confidence in using this easy to use orifice plate. Not only that. Measure pressure drop from position 1 to position 2 and calculate flow rate and more with this easy to use flow calculator Pressure drop formula calculation is published.

Micro Motion uses the term nominal flow rate. Since these meters have. The pressure differential is typically measured using diaphragm pressure transducers with digital readout.

Coriolis flow meters are very accurate better than 01 with a. In venturi tubes pressure loss is low and viscosity effect is high. There are no moving parts so there are no worn parts that cause low maintenance costs.

Expanded features include a customizable Target Card and an expanded Ballistics Data. Pressure control systems detect changes in process pressure and display the measurements in Bar KPa or other relevant units using the information obtained from pressure sensors. By using the smallest possible meter one will lower the initial cost and reduce coating build-up but will increase erosioncorrosion rates and head loss.

Kestrel 5700X Features at a Glance. Sizing Pressure Drop. Similarly ultrasonic flow meters werent made available on the commercial market until 1963.

This acceleration produces a measurable twisting force on the tube proportional to the mass. U and Ω shaped coriolis meters cause pressure drop as the flow is increased resulting in permanent pressure loss. As with these flowmeters the flow rate in a Dall tube is determined by measuring the pressure drop caused by restriction in the conduit.

DP flowmeters measure the drop in pressure across a flow element in the piping such as an orifice plate. Venturi tubes exist in sizes up to 72. As soon as the pressure recovers above the vapour pressure the bubbles impode.

Employs the Applied Ballistics bullet library of custom drag models an exact measurement of your bullets drag profile plus corrections for Aerodynamic Jump Spin Drift Coriolis and Drop Scale Factoring to achieve accurate extended long-range shots. Liquid or dense gas flows through a tube that is vibrated by a small actuator. There are no obstructions in the flow path so there is no pressure drop.

Differential-pressure flowmeter piping requirements. The measured flowrate is a function of the pressure drop. With Coriolis mass flowmeters the fluid runs through U-shaped tubes vibrating in an angular harmonic oscillation.

Consequently liquids near boiling point could introduced cavitation as the pressure across the meter drops below the vapour pressure of the liquid forming of vapour bubbles. Essential upstream pipe length of a venturi tube is 5 to 20 diameters. So the flowmeter consists of the flow element in the piping as well as a nearby differential-pressure meter.

Mass flow rates for stainless steel models. Pressure Control Monitoring. Because of the wide rangeability of Coriolis flow meters 301 to as high as 2001 the same flow can be measured by two or three different sized flow tubes.

What Is A Coriolis Meter Omega Engineering

Tricor Coriolis Flow Meter Tcm 028k Pressure Drop Curves Tricor Coriolis

No comments for "Coriolis Flow Meter Pressure Drop"

Post a Comment